My last post about removal and fitting of a bicycle head bearing, drew the following comment:

“Headset removal should be performed with a bike repair stand clamped to the bike’s seat post and definitely not to a frame tube, since you’ll be hitting the removal tool quite hard with a hammer.”

A valid point, one should never clamp a frame tube in a work-stand, and personally I would never do any kind of hammering on a frame even if it was held in the work-stand by the seat post.

I would simply place the removal tool in the headtube, hold the frame in one hand, while tapping out the bearing cup with a hammer or preferably a wooden mallet with the other hand. These cups are only a press fit in the frame, and only require a few light taps to knock them loose.

The reason it never occurred to me to mention this when I wrote the piece, not only do I not own a work stand, but I have also never owned one in my entire life.

Even when I had my frameshop, and occasionally had to build up bikes, I worked out of a vise, which was mounted on a steel pedestal and bolted to the floor. When working on frames I could move all around 360 degrees. With a vise mounted on a workbench, one can only work from one side.

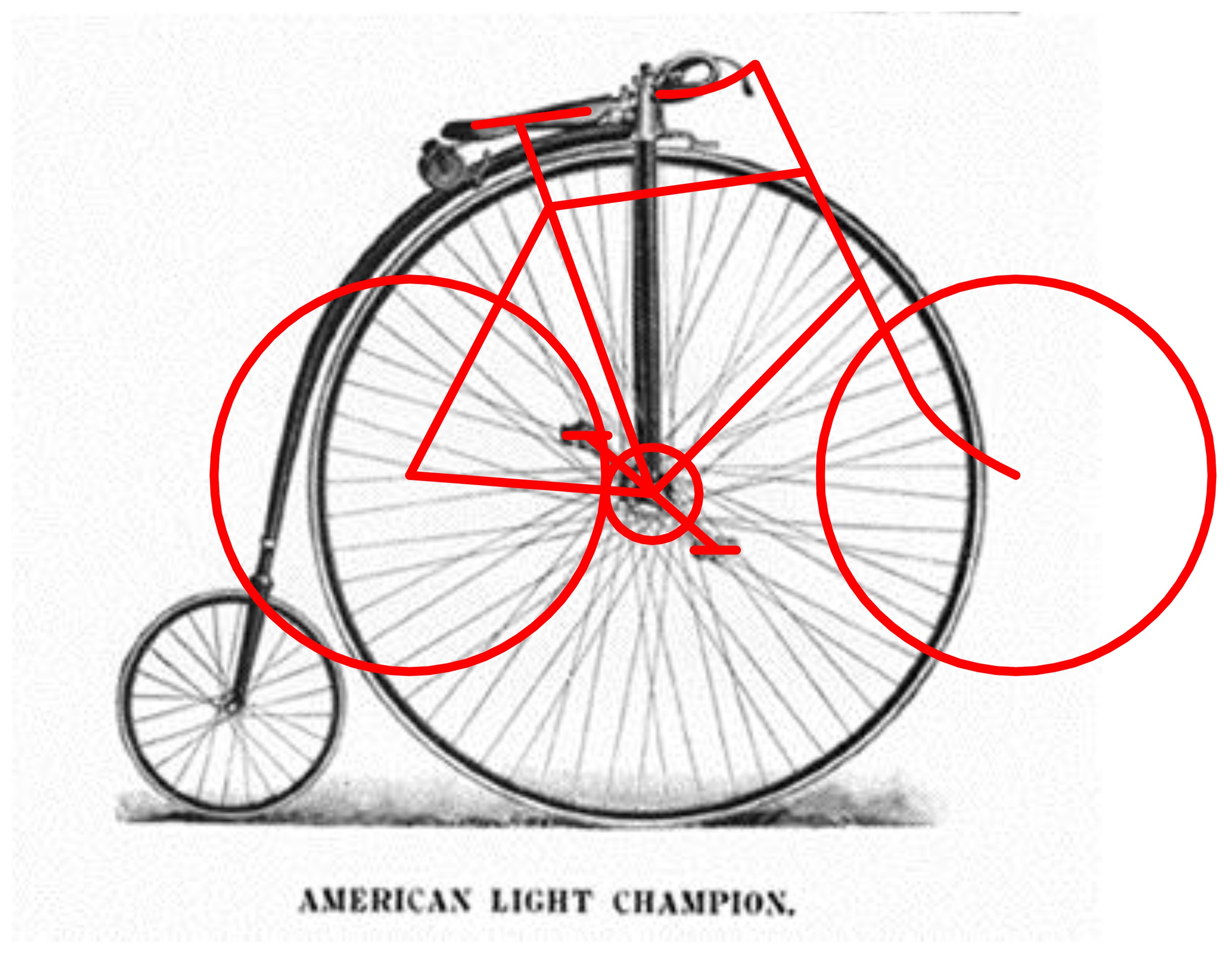

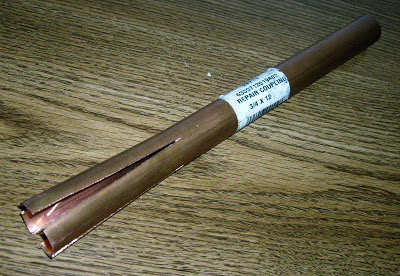

Obviously, I did not hold a painted frame in a vise, but I had steel mandrel that was a solid steel bar, 1.5 incches (38 mm.) diameter, with two flats machined on either side, so it would clamp firmly in the vise. The rest of the bar had been turned down in a lathe, to 27.2 mm. diameter, the same size as a standard seat post.

This was in effect a heavy-duty seat post that I used when prepping finished frames prior to shipping them to the customer. It served as an immediate check that the seat tube had been reamed to the correct inside diameter. I could fit a seat bolt and clamp the frame safely to the mandrel, while I fitted dropout and water-bottle screws.

The bottom bracket was faced, and threads cut on a machine before it was painted, and head tube was reamed and faced in a similar fashion. After painting, the paint had to be cleared form the bottom-bracket and other treads. This was all done with the frame safely mounted on this special mandrel.

If I occasionally needed to build a complete bike, I could quite easily fit bottom-bracket and headset bearings and even a chain-wheel, cranks, and pedals, with the frame still held in this fashion. A rear wheel could be added, and the front and rear derailleur fitted, and the limits set.

Remember that this was back when bikes were friction shift, so a chain could be added, and the gears adjusted and set to work correctly. All that was left to do was to unclamp the frame from the mandrel, fit a seat post and saddle, stem and handlebars, brakes, and the job was complete.

A work stand is pretty standard equipment in any bike repair shop where people are assembling, and working on bikes all day, but used without care by an inexperienced mechanic, and a great deal of damage can be done.

I got my first lightweight bike at fourteen years old, and could work on it, even build it up from scratch without the aid of a stand. I would fit the head bearings, and fork to the frame, as described in my last post.

Next fit a pair of wheels complete with tires, also a seat post, saddle stem and handlebars. I could now lean the bike against a wall and kneel to work on it or sit on a low seat. Fit the bottom bracket bearings and spindle.

Derailleurs could be added, and the limits set. Even with modern gears, if the upper and lower limits are set, and the cable tensions are correct, the gears will shift up and down and may only need minor adjustment after a short test ride.

I believe there is more damage done to frames in bike shops by miss-use of bike stands, than any other piece of equipment. If you are a newbie mechanic, learn by doing a few simple tasks without a work stand.

Save yourself some money and learn a lot, with less risk of doing damage. A bike work stand should be the last piece of equipment you buy, not the first.

Sun, November 5, 2023

Sun, November 5, 2023 It has been nine months since I posted here, so I feel I should at least post and update. It’s not that I have been idle since February, far from it. Some of you may know that as my bike business declined, I directed my creative thoughts to music, and in particular songwriting.