Book Review: Ignore Everybody

Thu, June 11, 2009

Thu, June 11, 2009  I became a fan of Hugh MacLeod about two years ago when I stumbled on his website gapingvoid.com.

I became a fan of Hugh MacLeod about two years ago when I stumbled on his website gapingvoid.com.

For those of you not familiar with MacLeod he is a cartoonist who draws cartoons on the back of business cards.

If you think that is a strange medium, it is, but it is original, and that has been part of Hugh’s key to success.

Hugh is definitely an inspiration to me, his success is self made, and he has undeniably paid his dues.

I was fortunate enough to get a pre-release copy of his book, (Release today.) Ignore Everybody: And 39 other Keys to Creativity. It is a must read for any artist, be they writer, musician, whatever.

For that matter anyone with a dream or idea, even a seemingly stupid idea like drawing cartoons on the back of business cards. Any budding entrepreneur starting a new business should read this book.

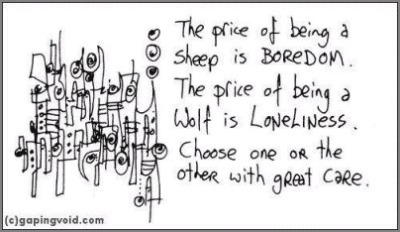

The title of the book Ignore Everybody is not meant to be taken literally; what it really means is ignore your critics. The naysayers who think you can’t possibly succeed. Here is an example of Hugh’s advice:

If your business plan depends on suddenly being “discovered” by some big shot, your plan will probably fail.

I sure could’ve used this advice as a teen. I used to walk around the streets of London carrying a guitar, thinking someone would discover me. I never even learned to play the thing properly, because I could tell Elvis didn’t really play, he had back up musicians.

Keep your day job

I know this is sound advice, for many years I had a day job and built frames in my spare time. Poverty not only sucks big time, it forces you to sell yourself short.

Hugh tells a story of how he was offered a book deal some years ago. He read over the contract, made some changes, and sent it back; he never heard from the publisher again.

The fact was Hugh MacLeod worked for an ad agency and had a good paying day job; he didn’t need the book deal on any terms. Now he has this book published by the Penguin Group; his patience was rewarded.

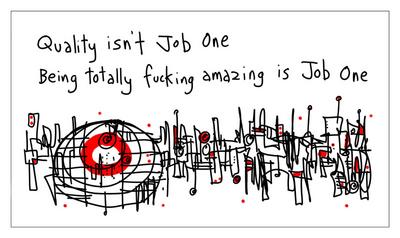

The most important thing a creative person can learn professionally is where to draw the red line that separates what you are willing to do from what you are not.

I can definitely relate to this. When I was struggling to get my business going in 1982/83 in Southern California, and was building custom frames; often a potential customer would come to me with frame specs or a drawing and ask, “Can you build me a frame like this?”

My answer was, “I can, but I won’t.” The reason was I knew a frame built to those specs would not handle as well as it should. The customer would not be happy and probably sell it; then there would be a bad handling bike out there with my name on it. My reputation as a curmudgeon enhanced my reputation as a framebuilder.

The best way to get approval is not to need it.

Again sound advice, like the last two quotes it is about sticking with what you believe in, and not compromising or selling out.

Remain Frugal

Good advice indeed for the artist or small businessman. Save for the lean times, because they will follow the abundant times as sure as night follows day.

Start Blogging

Use the Internet, although you make no money from blogging, it is free or relatively inexpensive, and you slowly build a following. Hugh MacLeod started his blog in 2001; gapingvoid now gets 2 million hits a month. He has a large enough following that he can sell limited edition poster size prints of his cartoons.

Ignore Everybody actually started out as a series of blog posts. The book is funny, Hugh’s cartoons are hilarious, and it is a step by step account of how someone can take a simple idea and see it through to fruition with determination and hard work.

Released in the US today June 11th, Ignore Everybody can be bought from Amazon.com, or from your local book store. In the UK it can be pre-ordered from W.H.Smiths, release there is not until 20th July

Art,

Art,  Book Review

Book Review

Consumer protection gone crazy

A strange state of affairs has arisen because of the passing of the Consumer Product Safety Improvement Act. (CPSIA) The act limits the amount of lead content in products intended for use by children under 12 years old.

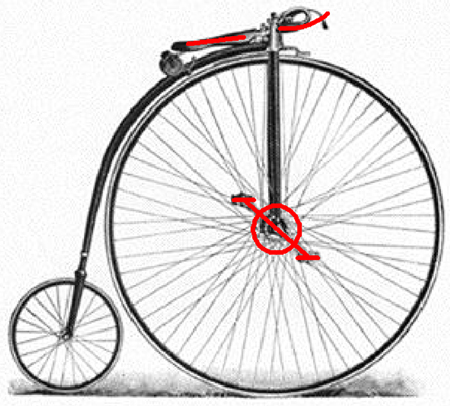

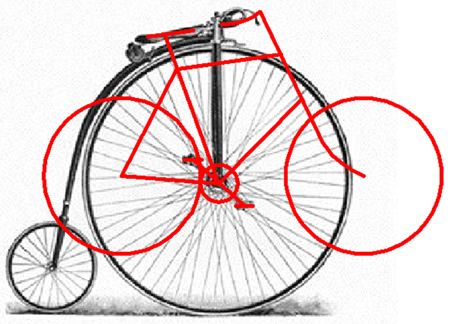

This act has now left manufacturers of children’s bicycles facing a huge problem, because certain parts of kids bicycles do not comply with the less than 300 parts lead per million that the new law requires.

Where is the lead content in a bicycle you may ask? It had me puzzled. It is in the brass used in the tire’s Schrader valve. Apparently the new regulations will also limit the industry's use of recycled steel and aluminum; both of which may or may not at some time or other be contaminated with lead.

The Bicycle Product Suppliers Association(BPSA) an organization that looks after the interests of bicycle manufacturers, applied for exemption from this requirement with the Consumer Product Safety Council. (CPSA) The CPSA is responsible for enforcing this legislation.

Exemption was denied, but a temporary two year stay on enforcement was granted, to give the bicycle industry time to find an answer to this problem. Not a real problem, just one of bureaucratic making. The reasons given for denial by the CPSC was, and I quote:

The BPSA was able to put forward scientific proof that a child riding a bicycle would be exposed to less lead than drinking regular tap water, or eating certain perfectly legal candy. No matter, the law it appears is inflexible, and it with take another Act of Congress to reverse it.

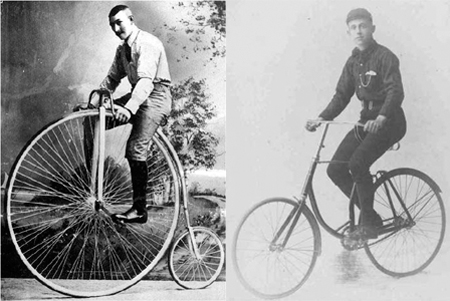

Also emphasized by the BPSA, that bike resellers such as Thrift Stores can’t comply with the new law because all used bikes have brass components. Dream Bikes, a Trek-sponsored nonprofit in Madison, faces the same problem.

It takes bikes away from the least privileged, and complicates the situation where a child outgrows a bike and the bike is sold or donated.

In the mean time the Bicycle Product Suppliers Association is facing extreme financial hardship. They have already spent their entire yearly budget of $100,000 in legal fees fighting not only this, but the ongoing New Jersey Quick Release ban.

Another prime example of our government in trying to protect us from ourselves, and in doing so creating more problems than they solve. And those of us from previous generations are left to wonder how we even made it thus far without all this protection

More reading on the subject in The Bicycle Retailer and Industry News. Also in these articles Overlawyered, and Bikes and Kids