Straightening steel forks

Tue, December 27, 2011

Tue, December 27, 2011  I came across a bike blog from Taiwan that happened to be linked to my blog; it showed a picture of a bike with a strange looking fork. The writer speculated whether it was a custom fork.

I came across a bike blog from Taiwan that happened to be linked to my blog; it showed a picture of a bike with a strange looking fork. The writer speculated whether it was a custom fork.

It was custom alright, but by accident rather than design. The rider had run into something solid, (Probably a car.) and bent the fork back.

To give this rider credit for ingenuity, it looks like he simply turned the fork around (Backwards.) and carried on riding.

Over the years I straightened many steel forks like this one, with complete safety and often not even damaging the paint. When you consider that a fork blade starts out as a straight tube; it is then rolled in a machine between rollers to make it tapered. This process is done cold.

The top end is pressed to an oval shape; this is also done cold. Finally the framebuilder cold bends the fork blade to the desired curve. So if the fork blade is bent once more in an accident, it can be re-straightened cold with complete safety as long as the tube is not kinked or rippled.

I would not recommend that this be done multiple times but once is okay. I will explain how it can be done.

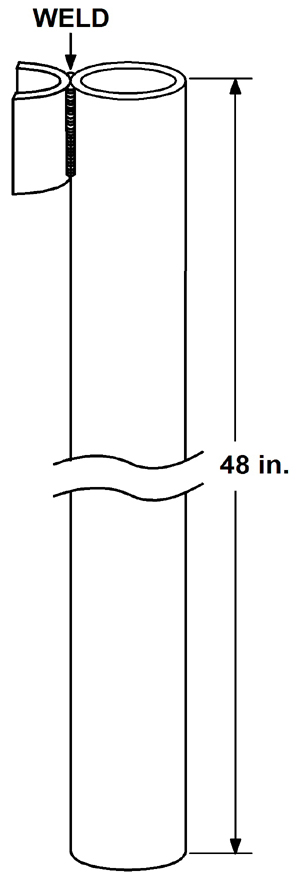

My fork blade straightening tool was a piece of one inch steel (Sometimes called black iron.) gas or water pipe about four feet long. One inch pipe measures 1 in. dia. on the inside, and is about 1 ¼ in. on the outside. (Picture right.)

I also cut a 1 in. piece of this same pipe then cut it in half to form a “C.” This was then welded to the top of the four foot length of pipe, and would form a cup to go around the fork blade near the crown.

I also cut a 1 in. piece of this same pipe then cut it in half to form a “C.” This was then welded to the top of the four foot length of pipe, and would form a cup to go around the fork blade near the crown.

This was padded on the inside of the “C” with several layers of duct tape to protect the paint.

Next take a piece of old bicycle chain about 10 inches long, make a loop by joining the ends using a chain rivet tool.

The fork needs to be removed from the frame; hold the steering column horizontally in a vise that is solid and won’t move.

Position the bent fork blades so they are sticking out horizontally on one side of the vise; left or right depending on which hand you use. Right side if you are right handed.

The fork should also be positioned so the blades are one above the other, and the bend that you are about to straighten is away from you.

Straighten one blade at a time by placing the chain loop over your four foot piece of pipe, and the other end of the loop over the fork tips. Place the “C” cup up near the crown above the bend, hold in place with one hand, and pull towards you with the other hand to straighten. Repeat to straighten the other blade.

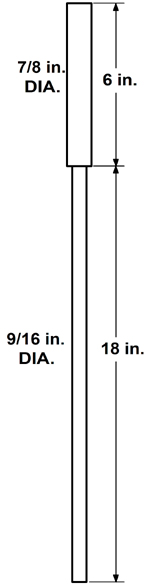

Now you will need to align the fork. I had a surface table with a fixture to hold the fork. However, most people will not have this luxury, so here is the next best thing. You need to make or have made another tool consisting of a piece of 7/8 inch solid steel bar, about 24 inches long. (Picture left.)

Turn down in a lathe 18 inches of this bar to a smaller diameter, about ½ or 9/16 of an inch. (Leaving 6 inches at 7/8 dia.)

Turn down in a lathe 18 inches of this bar to a smaller diameter, about ½ or 9/16 of an inch. (Leaving 6 inches at 7/8 dia.)

It does not have to be exact as long as it is small enough to pass easily through the butted end of the steering column. 7/8 in. is the diameter of a quill stem. (I am assuming this is an older steel frame with a one inch steering column.)

Slide the 7/8 in. portion into the steerer with the smaller diameter length reaching down between the fork tips. You now have a reference point that is dead center of your fork.

Ideally place a front wheel spindle between the fork tips, but failing that you can use a piece of steel bar 5/16 or 9mm. dia., or even a pencil at a pinch.

The fork tips need to be 100mm. apart, (Measured on the inside.) and centered on your special steel bar you have placed in your steerer.

The fork tips need to be in the same plane as the fork crown; a straight edge across the fork blades up near the crown can be sighted with your wheel spindle, or whatever you have between your fork tips. The fork rake or offset can be measured from the bar to the wheel spindle.

Also the straight part of the fork blades before the curve starts can be checked by placing a straight edge on both the front and back of the blades to see if the steel bar is centered.

In a front end shunt like this, the top and/or downtube sometimes get rippled. If this is the case the tubes need replacing as they will eventually break. The good thing about a steel frame is that it will rarely fail suddenly, but a crack will appear first and the frame will start to feel “spongy” as a warning before it fails completely.

Reader Comments (15)

For a fork to take that kind of a blow, surley the head tube had to also take a blow and bend and buckle the top top? Often on Ebay I see frames that are up for bid LESS the front forks, This to me, this suggest to me, that you should examine the frame VERY carefully BEFORE bidding.

Crumpy,

Sometimes a fork will bend and not the frame, sometimes the frame bends and not the fork. Othertimes both will bend; every crash is different. Or rare occasions the front wheel will colapse and the frame and fork is spared.

Dave

As Crumpy said, when hitting something head-on, usually both the fork, and the top and down tubes behind the head lugs, will bend. I have straightened such damage with the fork still in the frame by jacking between the bottom bracket and an axle bolted in the fork dropouts. I have a bottle jack with a length of 2x4 bolted to the base and cut out to rest against the BB shell on either side of the down tube. This works best with gaspipe frames. High quality alloy steel work hardens more when it's bent and may not want to bend back in the same place.

I'm presuming a similar rig could be used to re-rake a fork?

Dave's the expert, but I'd think changing the rake on a fork, you'd have to support the blades to control where it bends.

Increasing or decreasing the bend of the fork blades will change the rake but this has the effect of lengthening or shortening the fork. The small amount you can change this way is not worth the effort.

Dave

yes that is correct of course; as is turning the bars to align with intended direction of travel so as to coresponded with position of front forks. ie: spin the stearer 180* as a child might due. As we often overlook the obvious as expressed here; hence a barage of worthless feedback.

SOOOO! Is there ANY way to build a frame and fork so it will NOT get damaged in a frontal shunt? I remember a car a English Rover 2000TC that I had a couple off, in the 70s That claimed the engine in a front end shunt would go down under the passengers? or some such. Is the damage due the builder and his lack of knowledege. could the builder make the frame safer and less likley to damage in a shunt like this? By the way Happy New Year to Dave and everyone, John Crump. PS Why is the code to create post so dam hard to read, or is this just for me and my posts?

Thanks for the clarification. I was thinking of re-raking an extremely steep set of forks built with Reynolds 531C.

Thanks for this. If I can sort this my son will have a spare bike :)

Very reminisant of a Bates fork!

thanks for info dave, made a similar tool to yours and straightened some morrison 10 speed forks. it worked perfectly and did not require much effort!!

i drilled a block of wood and then cut it through the centre and held the post in the vice secure between the blocks so as not to mark the stem.

regards keith,new zealand

Thanks for the great write-up Dave! I found this while looking for ways to fix my Peugeot commuter that tragically flew off of my friends car when the roof rack decided it no longer wanted to be in a committed relationship with his car. Straightened the fork blades and realigned the after I made a set of tools like yours, and even got brave enough to fix the frame. It only had a very slight top/down tube bend, so a floor jack and some bracing took care of that.

I also was able to get a good deal on an AMR frameset in great shape because it had a very slightly out of alignment front fork. Which i now know how to fix!

Thanks again, and great site!

Mike Moore, USA

Well this was very helpful. Who wants to fork out a bunch of cash to have it fixed (especially right after a crash!) when they can fix it themselves. Your post was very well put together. Thanks for sharing!

my boss was requiring AR Complaint Form several days ago and was told about an online platform that hosts a huge forms library . If others are wanting AR Complaint Form as well , here's a

http://goo.gl/Ombtja