Straightening bent seatstays

Fri, November 16, 2007

Fri, November 16, 2007

I received the following email the other day, with pictures attached:

I was looking through your blogs (great stuff by the way!), and was wondering if you could lend me some insight.

I too am a steel bike rider and have a special fondness for Eddy Merckx bikes. One of my frames was bent by a shipper while en-route to a painter.

I collected insurance, and hung the bent frame on the wall with some other out-to-pasture items.

Now two years later, I figured I need another winter beater bike, and thought the frame wasn't that bad.

My friend suggested some wood blocks with carved out grooves the same diameter as the stays bolted around very close to the bends, clamping the frame with wood vices, and a very slow pressure to try to bend her back.

We're questioning the use of heat. Would that weaken the steel even more?

I know this will never be a racer or every-day bike again, but I hate to leave it hanging, and I really need another beater bike.

Thanks in advance,

Dave Whitney (davefromaine)

--------------------------

Dear Dave from Maine,

Never use heat to straighten tubes, you will end up with a kink in the tube, or it will crack and split. You could straighten it the way your friend suggests, but there is an easier way.

Leave the spacer shown between the rear dropouts, if you don’t have a spacer cut a piece of wood to fit tight between the rear ends.

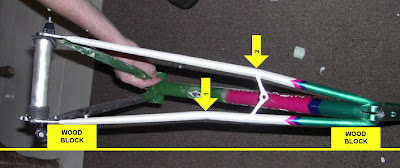

Lay the frame on the floor with wood blocks (cut from 2 x 4.) positioned as shown below.

Apply pressure with your foot at the point where the bend is (1.); in other words stand on it wearing a rubber sole shoe like a sneaker. Do it gently at first, depending how heavy you are, it will not take much.

I notice the left seatstay is also bent at the brake bridge. (2.) In all probability this will straighten as you apply pressure to point 1. If needed apply some pressure to point 2.

Check for straightness by looking down the seatstays from the top or bottom. Close one eye as if you are looking down a gun barrel.

If there is a dent in the tube this should not affect it structurally, and if you have the frame repainted in the future it can be filled with brass, and filed to the contour of the tube.

Finally do a string check for alignment. Tie a piece of string from the rear dropout on one side of the frame. Run the string around the head tube of the frame, and tie the sting to the opposite rear dropout. With the string stretched tight, measure from the string to the seat tube on either side. The measurement should be equal.

And you are good to go. That's the great thing about a steel frame; it is easy to fix.

Footnote:

When I worked at Paris Sport in NJ, a customer came in with a frame with bent seatstays exactly like the one shown here.

He asked, “Can you straighten this?” after I told him I could he asked, “How long will it take?”

“Couple of minutes.” I told him.

“Do you have a special tools to do this?”

“Yes, they are so special I keep them in leather cases.”

And I proceeded to straighten the frame as I described above, and handed it back to him two minutes later as promised.

Dave Moulton | Comments Off |

Dave Moulton | Comments Off |

Reader Comments (8)

Dave from Maine

Brilliant.

good story...how about illustrait how to stretch a rear end from 126 to 130...

thanks

nick in birmingham

I have a buddy who had his top tube trashed while it sat at a train station awaiting his arrival for the ride home. He has kidded with me regarding removing it and putting in a new one. Can that be done by a novice...and if so, how? It's an older Italvega steel frame with lugs.

Everything contained within the framebuilding article is absolutely spot on. Dave undoubtedly knows Ron Cooper (London) whose designs and workmanship is off the Richter Scale to say the least. Ron cut his teeth during the late 1940's in London working at factory and branched out from there realizing prestige to say the least. Ultimately his learned, later perfected (beyond imagination) construction style deliberately did not utilize jigs (save for fork) in lieu of the unstressed and perfectly aligned and pinned method that would also in some areas purposely "misalign" as the brazed tube section was notorious for "curving" off in a known post brazing direction, lessening the need for cold setting. Inspection of any Cooper frame more than validates what both Ron and Dave know.

I remarked these facts to a beyond self-important, know-it-all American frame builder sitting out in backwash Colorado whose use of jigs was absolute a few years back who disputed this, stating that such construction was not possible.

Oh.................., it's not? Whew knew? I could mention both Ron Cooper and Dave Moulton for starters, but why bother.

Dave, are you still building these days? Teaching? Cheers!